Dryer Cylinder Surface Passivation combines chemical (DusClean), equipment (MistRunner), and knowhow to reduce stickies & linting on the dryer cylinder surface.

Equipment

-

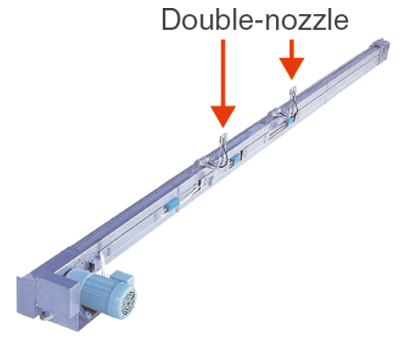

MistRunner

*Specially designed air curtain with over 90% spraying efficiency

*Heat-proof in dryer hood at more than 120˚C / 248˚F

*Double-nozzle for wide and high-speed paper machine

-

Chemical

-

DusClean

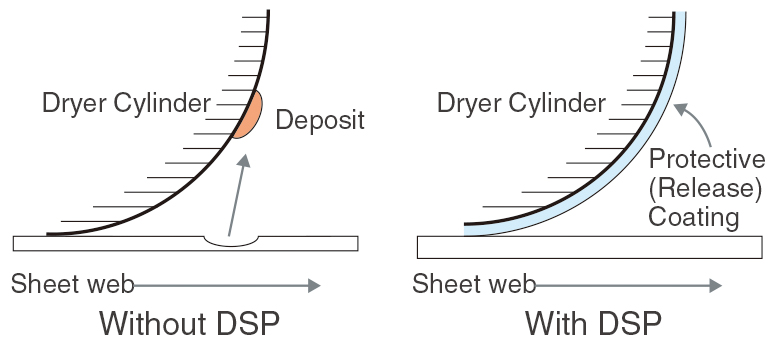

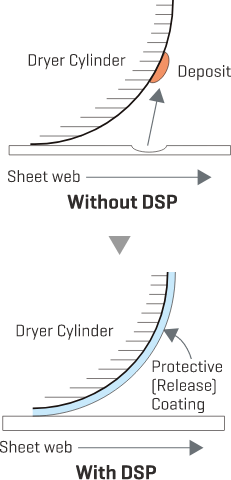

*Establishes a protective coating that prevents stickies buildup and linting.

*Components: vegetable, mineral, synthetic & silicone oil + wax emulsion

-

Application

-

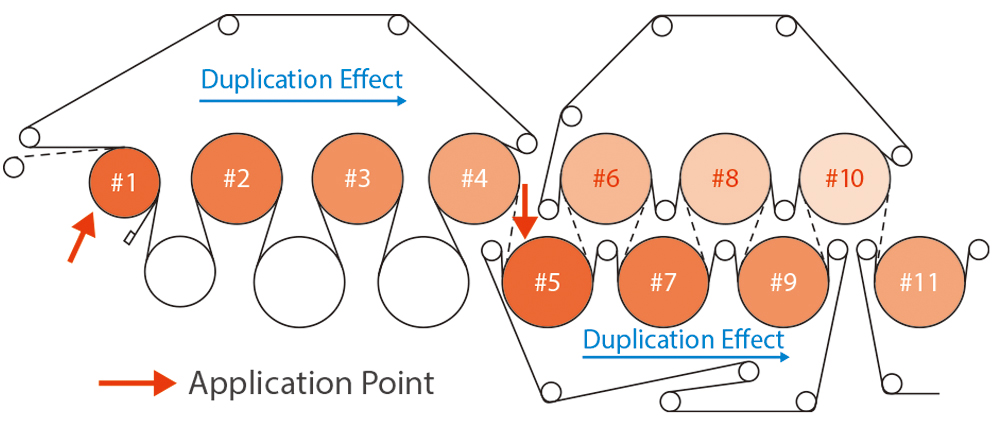

**Utilize MistRunners to apply passivation chemistry on each side of paper

*Establishes stickie-free and linting-free coating on cylinder surface

*Stickie and linting prevention effect extends to subsequent cylinders

-

Key Benefits

①Reduced sheet breaks⇒Increased production

②Reduced cleaning work⇒Improved productivity = Labor saving

③Improved sheet quality⇒Reduced end user complaints

④Reduced steam consumption⇒Increase drying capacity

⑤Extended doctor blade life⇒Cost reduction